Guide to Our Decoration Methods

At VPPStore, we take pride in offering an extensive range of high-quality decoration options. Our dedication to innovation means we are constantly exploring and testing new techniques to provide the most advanced embellishment methods available. Whether you're looking for traditional or cutting-edge imprinting techniques, we have a solution to fit your needs. Below, we outline some of the many decoration methods we offer, each with its own unique application and benefits.

If you have any questions about which decoration method is best suited for your product, please contact us at 1-800-868-7018 or email customerservice@vppstore.com.

Screen Printing

Screen printing is a widely used technique where ink is applied to a surface through a stencil that is supported by a fine mesh fabric stretched tightly over a frame. This method allows for various ink applications, including raised ink, metallic finishes, color-changing inks, and more. Screen printing is an excellent option for producing vibrant, long-lasting designs on apparel and other surfaces.

Digital Printing / Direct-To-Garment (DTG)

Digital printing, also known as Direct-To-Garment (DTG), involves printing dye or ink directly onto a fabric surface, making it ideal for detailed, multi-color designs. This method is perfect for small quantity orders that require a high number of colors. DTG printing is particularly well-suited for 100% cotton garments and includes up to a 7-color imprint with a standard size of up to 5" x 5". Larger sizes are available upon request—please contact us for a quote.

Digital Printing / Direct to Film (DFT)

DTF printing is a method of transferring designs onto garments and textiles using a specialized process. It begins with printing a design onto a PET (polyethylene terephthalate) film using a DTF printer with water-based pigment inks. While the ink is still wet, a hot-melt adhesive powder is applied to the film, which is then heated to cure the adhesive. Once ready, the prepared film is placed onto the fabric and transferred using a heat press at high temperature and pressure. After cooling, the film is peeled away, leaving a vibrant and durable design adhered to the fabric

Heat Press / Heat Transfer Printing

Heat press printing, also known as heat transfer printing, is a process where heat-applied materials are transferred onto a product using a heat press machine. This method allows for full-color designs up to 8-1/2" x 12" and is commonly used for apparel and fabric-based promotional items.

Engraving, Etching & Laser Engraving

Engraving and etching techniques involve cutting a design into a hard surface, such as glass, metal, or wood, revealing the material color beneath. Laser engraving offers precision and is an excellent option for adding a sophisticated, permanent touch to your product.

Engraved Enamels / Enamel Medallions

This method involves filling metal plates with colored enamel, which is then laser engraved with your logo or design. The engraved plate is securely affixed to a product’s surface using a strong adhesive, offering a sleek, professional finish.

Epoxy Domes

Epoxy doming involves printing a logo or design on paper and sealing it under a clear, high-gloss acrylic dome. This method provides a sleek, dimensional effect and enhances the durability of the printed design. The epoxy dome is then affixed to the product's surface.

Medallions / Metal Stamping / "Steel Threads"

A custom-made die is used to stamp your design onto a metal plate or disk, which is then affixed to the product's surface using a strong adhesive. This method provides a premium, metallic finish, with common color choices including Matte Silver, Antique Silver, Antique Brass, Pearl Nickel, and Matte Black.

Molded Rubber Patches / "Logo 3D"

Molded rubber patches offer a bold, dimensional look and come in a variety of colors and shapes. These durable patches are applied to a product’s surface with a strong adhesive, making them an excellent option for branding on apparel and accessories.

Pad Printing

Pad printing is a versatile decorating method that transfers wet ink onto irregular, curved, or textured surfaces. It is widely used for promotional products such as mugs, pens, and golf balls, providing a clean and professional imprint.

Stamping (Hot, Foil, or Color Stamping)

A custom-made die is used to apply your design onto a surface using colored foil or heat. This method is commonly used on leather and vinyl products, giving a stylish, high-end finish.

Sublimation / Dye Sublimation

Dye sublimation is a process where heat evaporates pigments from a carrier film, transferring them onto a product's surface. This technique is frequently used for producing full-color graphics and photographic images on items like mouse pads, mugs, and nylon banners.

Debossing

Debossing is the process of pressing a custom-made die into a material’s surface to create a recessed design. This technique offers a subtle and sophisticated appearance, making it ideal for leather and vinyl products. Additional options for debossing include:

-

Blind Deboss – A traditional deboss with no added color.

-

Color Stamp – Adds colored foil to the debossed area for contrast.

-

Color Fill – Fills the recessed design with color for enhanced visibility.

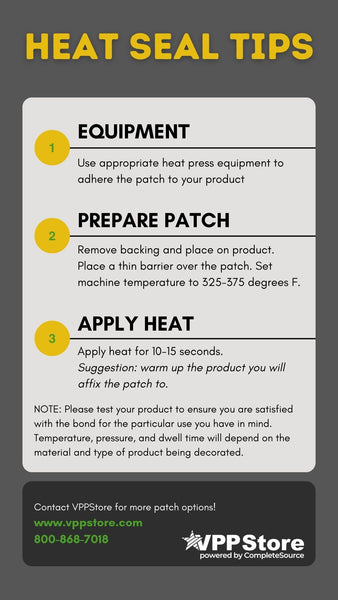

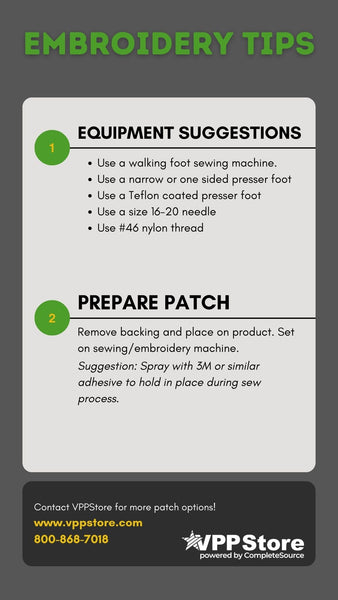

Patch Application

VPPStore offers a variety of stock patches as well as custom patches for branding apparel and other materials. Contact us to create a patch design that meets your specific branding needs.

For more information about our decoration options or to get a quote, reach out to us at 1-800-868-7018 or email customerservice@vppstore.com. We look forward to helping you create high-quality, customized products!

|

|